TireX Advanced Thermal Sensor

TireX advanced thermal sensor

Description

The most advanced thermal imaging sensor for motorsports

TireX is a thermal imaging sensor that visualizes how your tires are working, in real time. Use it to tune your suspension for maximum grip and balance.

Next-generation technology

TireX uses the most advanced sensor technology in its class. Not only does it have superior accuracy and thermal compensation than current sensors, it’s thermal array design allows applications beyond measuring tire temperatures. There’s no sensor like TireX at any price!

Better grip, faster lap times, win races

TireX will show you how evenly your tires are working, helping you identify where to make changes to your suspension. Maximize your tire’s grip to get faster lap times and win races.

Wide field of view works with your tight fenders and wide tires

110 degree field of view (FOV) simultaneously reads multiple zones across your tire.

See the FAQ for a guide on how far to mount TireX away from your tire!

Up to 16 temperature zones supported

You can select 1, 2, 4, 8, or 16 temperature zones per tire, enabling fine resolution when you need it – up to 64 channels of data with 16 zones and 4 corners!

Actual real-time 16 channel thermal data (cup of hot water for demonstration)

Assign each sensor to a vehicle corner

Each TireX sensor can be assigned to a corner of the vehicle, reporting each sensor’s position with zones properly reporting inside edge to outside, regardless of left or right location on the vehicle.

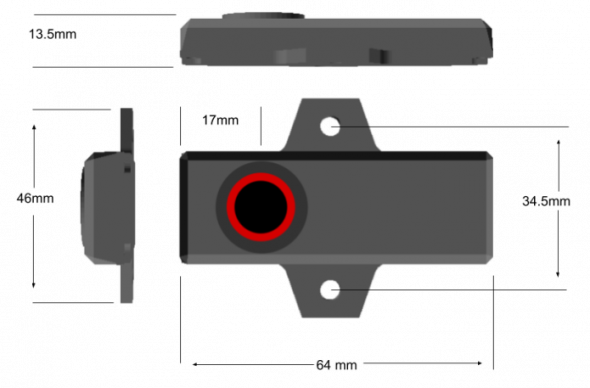

Rugged and compact

TireX was carefully designed to keep a low profile mounting in mind, and specifically for mounting above the front tires to minimize steering-induced reading errors.

High quality connectors

TireX comes with a rugged and compact industrial M8 connector for integrating with your wiring harness.

You only need 4 wires if you’re doing your own wiring: 12v power, ground and two CAN bus connections.

However, you can choose our ready-made four-corner plug and play harness, saving hours of wiring time:

RaceCapture owners

Order the optional parts to make a 100% plug and play solution – no custom wiring. See the quick start guide to see how easy it is to set up.

Compatible with Podium real time telemetry

Easily analyze tire temperatures right from the pits and figure out what you need to tune before the car even comes into the pits! Three unique data visualizations are offered for TireX – optimized equally well for real-time data as well as after-session review. Learn more about Podium

Compatible with most popular data systems

Simple CAN bus protocol makes integration easy with virtually any modern data system supporting CAN bus, such as AiM, MoTeC, AEM and more.

See the finalized CAN bus protocol for the complete documentation.

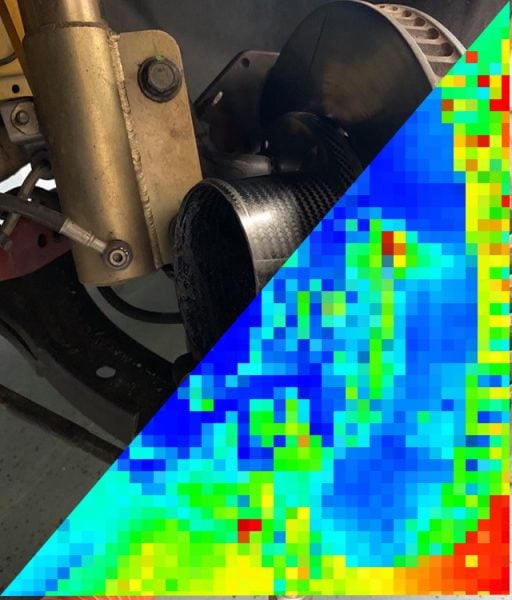

Advanced thermal imaging mode

The capabilities of TireX go beyond measuring tire temperatures: The 16 x 12 thermal imaging sensor generates 192 channels of data that you can use to monitor hot spots on your race car in real time, while on track. You can use it with Podium real time telemetry, or with any analysis package capable of visualizing this advanced data!

(Simulated example)

Actual thermal image real-time telemetry with Podium

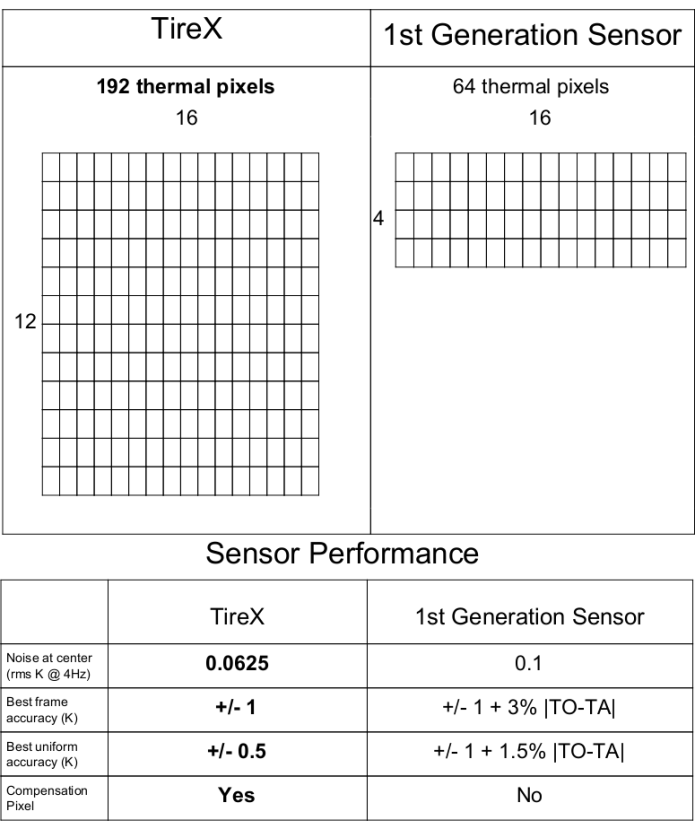

Next generation technology

Not only does TireX support advanced thermal imaging capabilities, its latest generation sensor technology offers approximately 2x better noise performance and improved thermal compensation vs. other sensors in its class.

Want to compare existing first generation sensors? Those are the devices that specify 120, 60, or 40 degree field of view (FOV).

Plug and play harness option

Save hours on installation time! The optional plug and play harness makes it incredibly easy to wire and minimizes errors – just plug the sensors into the harness, then run the loop around your vehicle, locating a sensor at each corner.

After routing, it’s just two wires for data, and two wires for 12v and Ground!

CAN bus protocol – ready to go!

TireX’s CAN bus protocol is finalized and ready to be integrated with your system. See the protocol information on our wiki.

Fully customizable

All of TireX’s settings can be customized via software (CAN bus) command, and these settings are saved in non-volatile flash memory so they are retained across power cycles.

Ordering information

TireX is available as a pre-configured 4 zone kit (left-front, right-front, left-rear, right-rear) as well as single sensors.

- 4 zone kit SKU ASL_TIREX_4PACK

- Single sensor SKU ASL_TIREX_SINGLE

Complete specifications

| Feature | Description |

|---|---|

| Sensor type | Thermal array |

| Sensor Resolution | 16 x 12 (192 pixels) |

| Object temperature range | 0 – 127.5C (tire temperature mode) / 0 – 255C (full frame mode) |

| Field of view | 110 x 75 degrees (55 x 35 upon special request) |

| Accuracy | 1C |

| Temperature zones (tire) | 1 / 2 / 4 / 8 / 16 |

| Sample rate | 0.5 – 64Hz (Tire temperature mode) 0.5 – 10Hz (Full frame mode) |

| Processing Engine | 32 bit |

| Configurable positions | 4 (Left-Front, Right-Front, Left-Rear, Right-Rear); Reversible orientation |

| Emissivity | Configurable (0.95 default) |

| Ambient temperature compensation | Automatic (adjustable offset) |

| Electrical | |

| Interface | CAN 2.0 |

| Supply voltage | 6 – 12v |

| Power | 200mW |

| Harness | M8 4P Male, 250mm length |

| CAN bus | |

| CAN baud rate | 500K and 1M, jumper and software configurable (500K default) |

| Address space | 4 separate address spaces (configurable via jumper) |

| Termination | No Termination (configurable via jumper) |

| Physical / Environmental | |

| Construction | CNC aluminum |

| Dimensions | 64 x 46 x 12.5mm |

| Weight | 10 grams |

| Operating temperature | -40 – 85C |

| IP rating | IP65 |

View the extended specifications and installation guide in our wiki.